cuelathe

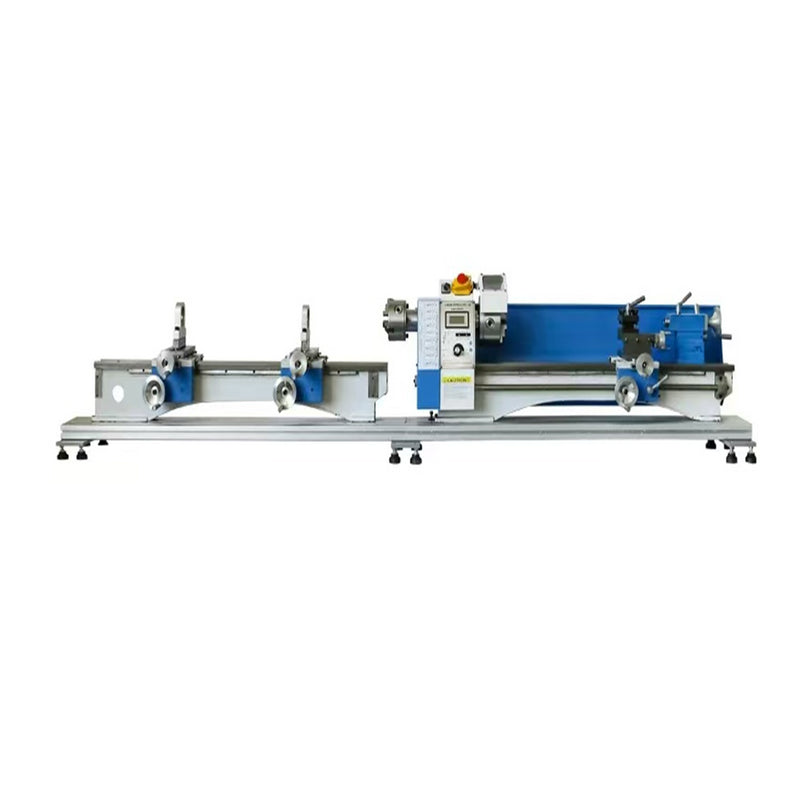

Casting bed 210 lathe double head chuck cue repair machine, double head chuck cue repair lathe, 210 lathe table tennis cue repair machine, cue lathe

Casting bed 210 lathe double head chuck cue repair machine, double head chuck cue repair lathe, 210 lathe table tennis cue repair machine, cue lathe

Couldn't load pickup availability

Fixed on an integrated aluminum alloy base, 750 stroke, 900W brushless motor, 38mm spindle through hole, 100 metal chuck on the outside, 125-3 jaw metal chuck on the inside, 750mm processing length inside the bed guide rail, clamped by the outside chuck, and the tool table on the bracket and the tool table in the lathe position. After clamping, the clamping force of the inner and outer chucks and the hijacking ability of the outer bearing seat, extrusion and straightening, are suitable for use in clubs or your own billiards and billiard rooms.

[Material]: The billiard cue repair machine uses a 210-750 metal lathe as the main machine. The main machine body is made of quenched cast iron, which has high hardness and good stability. It is equipped with a cast iron island as the auxiliary support system for the cue handle, which has higher overall stability, wear resistance and long service life;

[Motor]: The pool cue repair machine is equipped with a 900W brushless motor, voltage of 110V, 60Hz, American standard plug, equipped with forward and reverse stepless speed regulation and digital display function, speed 0-1400r/min, strong power, stable operation, low noise, long service life;

[Spindle]: The spindle through hole of the pool cue lathe is 38mm. The left chuck is a 100mm three-jaw chuck, and the right chuck is a 125mm three-jaw chuck. The cue clamping stability is good, the accuracy is less than 0.001 inches, and the operating space is large; the right chuck can be equipped with a 125mm four-jaw chuck or a six-jaw chuck;

[Drag Plate]: The pool cue lathe machine adopts a lathe-type high-precision drag plate, which has good feed stability and is equipped with an automatic tool feeding function;

[Tailstock]: The pool cue repair lathe machine adopts a high-precision adjustable tailstock and is equipped with a 1.5-13mm drill chuck, which ensures precise centering and more stable drilling;

[Tool holder]: The pool cue lathe machine uses a four-station ordinary tool holder, and can be equipped with a European-style quick-change tool holder;[Tool holder]: The pool cue lathe machine uses a four-station ordinary tool holder, and can be equipped with a European-style quick-change tool holder;

【Machine Function】: The pool cue repairing machine can repair the leather tip, copper hoops, and lead angle of various cues, customize copper hoops and lead angles, maintain cues, change tapers, wrap handles, straighten, connect teeth, change counterweights, slot, wrap handles, etc.

Main functions: repairing leather heads, changing the first angle and copper hoops, customizing the first angle and copper hoops, grooving the back handle, winding, wrapping the handle, changing the male and female teeth, making female teeth, adding or removing counterweights, repairing loose counterweights, opening the wire, polishing, grinding, maintenance, and straightening.

Motor Power: 900W

Voltage:110V/220V

Frequency: 50Hz/60Hz

Continuously Variable: 0--3000(Kw/rpm)

G.W/N.W: 138kg/108kg

Size:2260mm*390mm*390mm

Packing Dimension:1340mm*510mm*510mm+1270mm*450mm*460

Share